Production Process

-

01

01Mixing

Process of mixing artificial silica + sodium silicate + water in an optimal ratio -

02

02Create Molding

Process of making molds to allow molten metal to be injected -

03

03Combination

Combination of upper and lower part of molds -

04

04Preparation

Preparation process to increase the internal temperature of molten metal -

05

05Melting

The process of charging and heating metal material into furnace to turn solid material into liquid state -

06

06Injection

Process in which molten casts are poured into mold when they reach certain temperature -

07

07Coagulation

Adjust the castings injected into the mold at a certain time and speed to prevent cracking and contraction deformation -

08

08Sand Blast

Process of removing molding sands on the product after the mold is dismantled -

09

09Cutting

Process of cutting out the hot-potter, pressure-potter, etc. attached to the product -

10

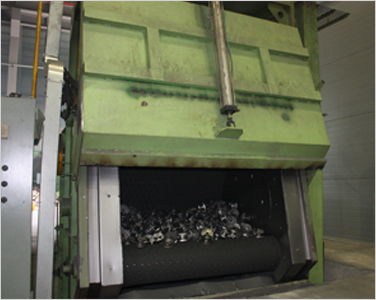

10Shot Blast

Process of shaking off the sand attached to the castings -

11

11Dimension Inspectiojn

Process of inspecting castings and drawings for conformity with the required dimensions -

12

12Heat Treatment

Process that improves the mechanical properties of metals, such as hardness, ductility, strength, and toughness -

13

13Shot

Surface treatment process for castings